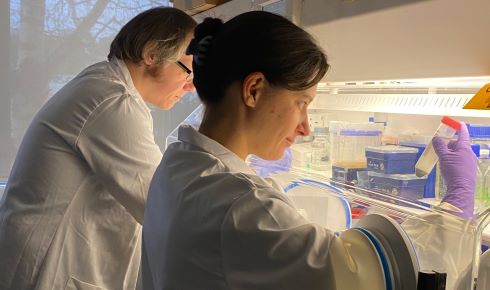

My Lab Unlocked: Professor of Sustainable Biotechnology, Louise Horsfall FRSB

Professor Louise Horsfall on using microbes to generate in-demand materials, such as lithium, from waste

Certain bacteria have the ability to form metal-based nanoparticles allowing them to survive in what might otherwise be toxic concentrations of metal ions in a solution. Mechanisms to do this range from the reduction of cations to zero-valence pure metals, to the production of carbonates that mineralise the ions.

Using synthetic biology tools and techniques, my research team aims to enhance, manipulate and standardise the biomanufacture of these nanosized precipitates as high value materials. Our ultimate aim is to produce engineered microbes with the ability to upcycle technology-critical metals from waste streams into high value nanoparticles, with exciting applications in the green technology sector ranging from batteries to catalysts.

This area is growing in importance, and as we rapidly transition away from being a society dependent upon fossil resources, we are going to massively increase society’s dependency on metals. Metals have a finite supply and are resource-intensive to obtain, but can be used within a circular economy for centuries, if there are the advanced recycling technologies to enable it.

Experimentation with non-model bacteria and limiting the impacts of their phenotypic diversity is challenging, even at the lab scale. Research in my team is looking to develop and scale bioprocesses that are robust enough to contribute to the suite of sustainable treatment methods needed to deal with the predicted 235,000 tonnes of end-of-life vehicular lithium-ion batteries available for recycling by 2040. As has been said many times over, scale up is a big challenge for biotechnological processes.

We have developed a route for using bacteria to recover the metals from lithium-ion battery cathode material. The bacteria used in our process benefit from being able to transform the solvated metals into nanomaterials, as it is part of their remediation strategy, so evolutionary pressure aided by engineering biology keeps the desired characteristics.

I believe that this has helped us rapidly replicate small-scale results at local scale-up facilities. However, such facilities would need to be enormous to deal with the projected amount of end-of-life battery material available in future years. And, despite our comparative assessments, demonstrating a bio-based process makes better use of resources than currently available chemical methods. There are also huge challenges ahead in being able to convince already-established companies in the sector that biology can provide a more sustainable recycling solution than other more recognisable technologies.

Not only is the work we are doing quite unusual in requiring molecular biology, industrial biotechnology and physicochemical characterisation of nanomaterials, but our cross-discipline collaborations are also unique. We have worked within the ReLiB project of the Faraday Institution for almost six years. This dynamic team of researchers from Birmingham, Leicester, Newcastle, UCL, Imperial and Oxford have provided us with samples of real car batteries, demonstrated methods to extract lithium from brines, taught us life cycle assessment methods, and are now trialling our recovered materials in new batteries.

Moreover, we have recently secured EPSRC funding alongside Birmingham and Leicester for a circular economy research centre, that will allow us to further our collaborations through the development of advanced recycling technologies for other green technologies, and we are looking forward to examining the biological recovery of a wider range of critical metals.

The Horsfall Group is developing recycling methods to deal with the vast numbers of end-of-life lithium-ion batteries

The Horsfall Group is developing recycling methods to deal with the vast numbers of end-of-life lithium-ion batteries

COVID limited our research outputs, as it did for the vast majority of groups because it limited researcher numbers in the lab. My team were already squeezed into a relatively small space so the challenge was to try to manage the limited access we had as fairly as possible, while supporting each researcher’s individual needs. Credit must go to Dr Mike Capeness, my lab manager, for the logistics of organising access and implementing the required distancing - he’s an absolute star and we would have been lost without him.

When I first started as a PI, over a decade ago, I was fascinated by the emerging field of synthetic biology and motivated by resource efficiency. However it took an EPSRC sandpit and numerous lengthy discussions with non-bioscience colleagues for me to see the potential in this particular field of application. Since then, my research team has grown in number, as has the size of our aspirations. We have shown multiple times that ‘biology can do it better’ but my proudest achievement is the research environment that we have created together, one where we support each other to cross boundaries, develop new skills and ask (sometimes stupid!) questions.

Find out more about the Horsfall Group

Professor Louise Horsfall FRSB is a professor of Sustainable Biotechnology at the University of Edinburgh’s Centre for Engineering Biology